- 特种机

- 数控多功能全自动旋转模板机

- Model JT-K10

- 先进工艺与技术创新,提供高质量自动化设备。

Based on the principle of mechanical engineering, provide a fast & stable solution for lower button feeding

1.360 degree surrounding style button feeding device, feeding the button precisely with ultra-high speed

Feed the button with ultra-speed and no button drop, adopt 360 degree surrounding style button feeding device, buttons move in the device quickly and precise, no button drop and don't need adjust the device. avoid the defect of traditional fork style button feeding device.

Feeding the button precisely. Surrounding style feeding the buttons freely, avoid the button position skewing, avoid the tracking adjusting question of the traditional fork style button feeding device.

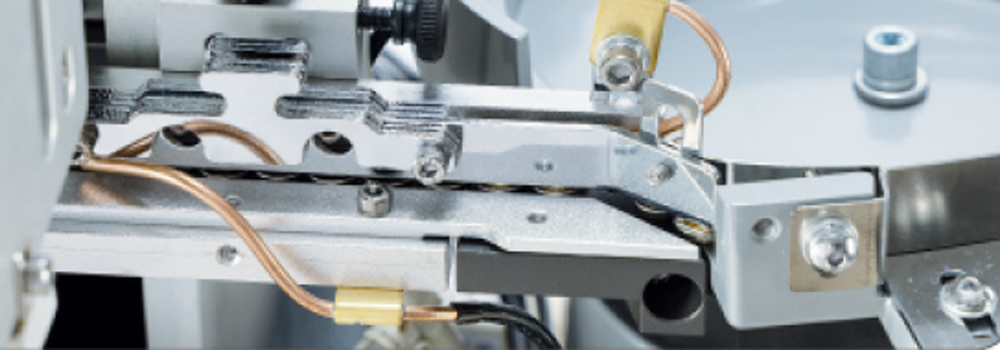

2. Adopt three-steps button feeding mode, more reasonable and more stable

Adopt three-steps button feeding made is controlled by intelligent motor. The first step is clamping the button, this step is on paralleled track, to avoid the position drop of the buttons; the second step is releasing the button, the button be releasing at vertical direction by motor control, release the button stable and the height can be adjusted by electric method; the third step is feeding the button to the correct position precisely, and the feeding position can be adjusted according to the button, operating more convenient. The three-steps mode avoid the defects of traditional two-steps button feeding mode, such as button position drop, clamping button not precise, adjusting problem of machenism, etc.

1. Adopt PLC control system, machine works more stable

The PLC system is very powerful to control the motors and cylinders of automatic button attaching machine, can avoid the system problems of the machine.

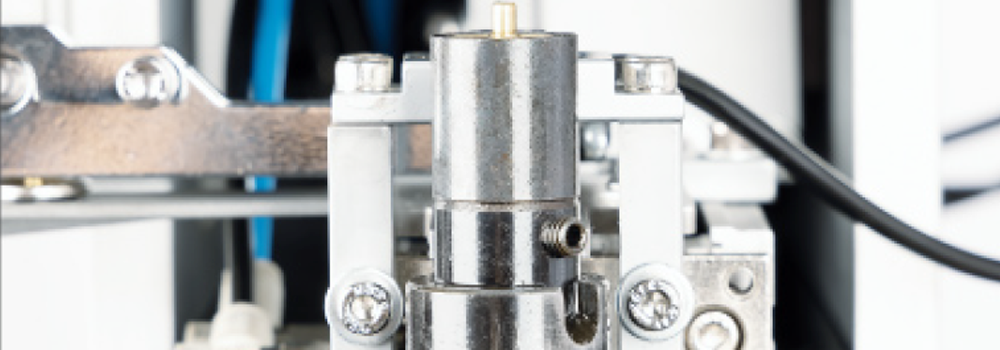

2. Adopt 360 degree active following punching mold seat

Punching mold seat adopt error correction structure, the mold seat keep 360 degree following to make sure the punching seat and the the punching bar keep at same position when the punching bar is working. This structure can not only ensure the accuracy of punching, but also can avoid the damagement of the punching seat.

3. The adjusting of feeding track is easy and precise

Adopt standard card style track, don't need change the track when change one button to another one, just need insert the card to adjust it. The adjusting is Easy and simple. Avoid the track out of shape which caused by the screw adjusting of the track.

4. Upper mold seat can be adjusted concentrically 360 degree, riveting more precise

Adopt concentric bushing & shaft adjusting structure to keep the upper mold always keep at same position, reveting more precise. Avoid position error.

5. Self-adaption device to suit all kinds of fabric

Adopt cushion spring at the core adjusting point, to make the machine self-adaption. This structure can not only protect the button, but also can ensure the riveting power.

6. Easily to attach the buttons for finished clothes, pocket and lower button

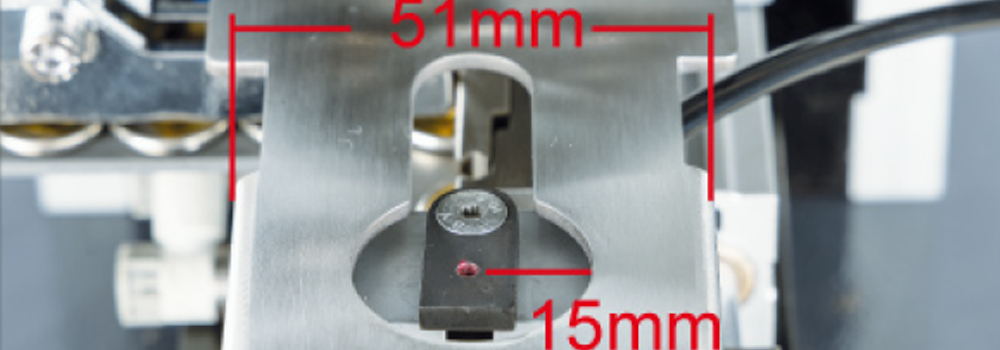

15mm The operating platform adopt cylinder-bed and narrow edge degisn, width 51mm, the distance

between the edge and the center point of the mold is only 15mm, easy to attach buttons for finished clothes, pocket and lower button.

7. High-end industrial motor to ensure the power output

Adopt high-end industrial motor to ensure power output, more durable.